Recent graduates from Conestoga's Welding Engineering Technology - Inspection program had their capstone project recognized nationally in the CWBA - WELD journal.

Conestoga students Soveigh Brasseur and Michael Brennan completed a study of a novel approach to the volumetric inspection of a steel component using ultrasonic inspection technologies.

Soveigh Brasseur and Michael Brennan, under the supervision of professor Tam Nguyen, completed their study of a novel approach to the volumetric inspection of a steel component using ultrasonic inspection technologies.

The steel component was produced at the Cambridge - Fountain Street campus using wire-arc additive manufacturing (WAAM) methods that the college has been developing through a range of applied research projects.

The WAAM process uses an electric arc to melt and deposit engineering alloys. It combines arc welding, industrial robotics and programming to transform a welding robot into a large-scale 3-D printer of metal shapes -- an alternative to traditional metal manufacturing methods such as casting, forging or machining raw billets to produce a desired shape.

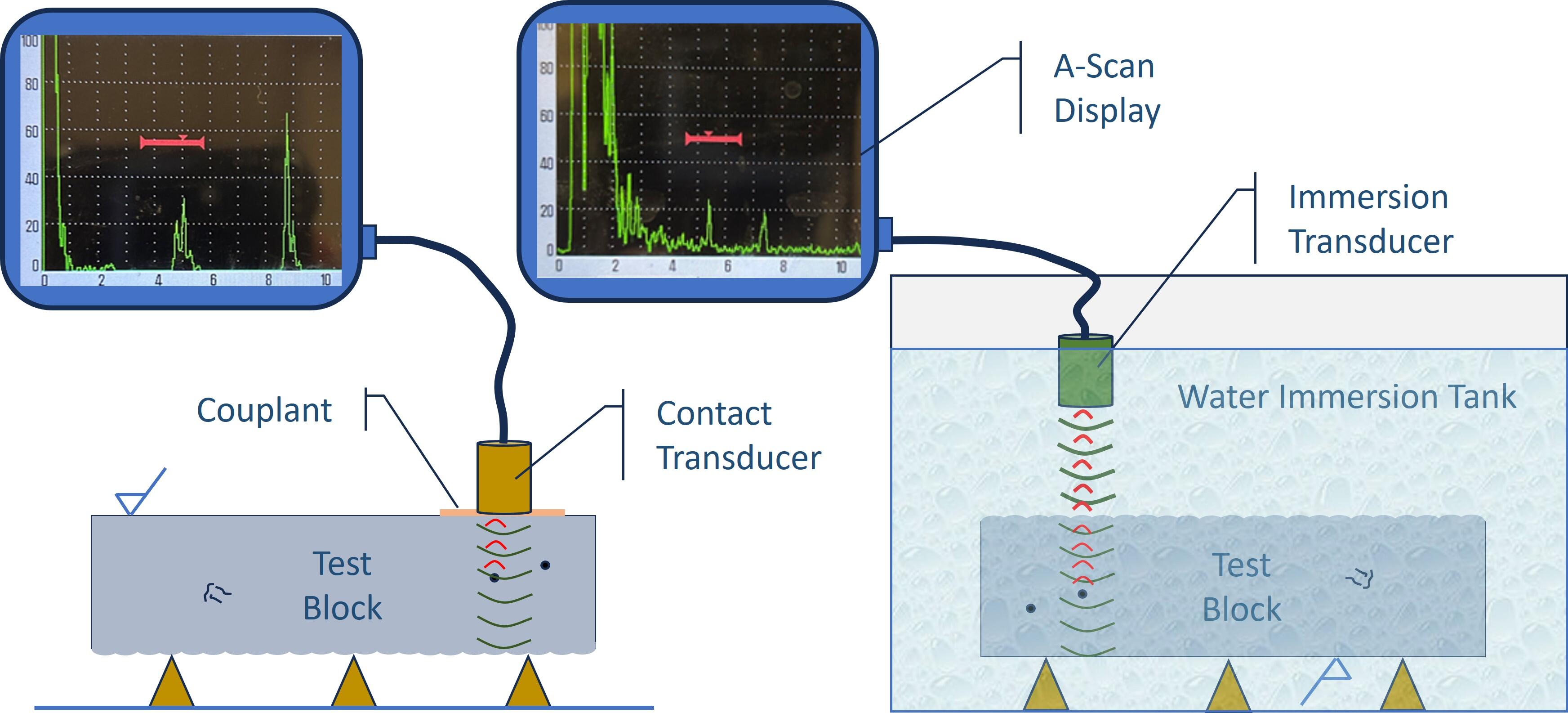

This "exceptional" third-year student project advanced that process by finding a way to perform an internal quality assessment of the material produced, said Jim Galloway, professor and co-ordinator of Conestoga’s welding programs. Industrial ultrasonic technology was used similarly to a medical ultrasound to see inside the material, Galloway explained.

To validate the inspection process, intentional defects were placed inside the component as it was printed, including cracking, pores and inclusions. Using the specialized ultrasonic testing methods, the students detected the defects, even through the rough, as-welded surface of the component.

The article in WELD journal authored by the Conestoga students said one potential application would be the development of replica components for the training and qualification of non-destructive testing technicians.

"Critical plant components could be printed, and specific internal discontinuities could be engineered as and training personnel," they wrote.

Welding Engineering Technology - Inspection is a three-year advanced diploma program with optional co-op. Students gain a balanced education in welding engineering technology, combined with practical work in metal fabrication, welding, robotics, metallurgical, and non-destructive testing laboratories.

The college works in collaboration with industry, community and government partners to deliver innovative solutions to address real-world challenges.

Conestoga consistently ranks among Canada's top research colleges, supporting the needs of industry and community partners while providing students with opportunities to build skills. The college was ranked 17th of the Top 50 research colleges in 2023.

Visit Conestoga Applied Research and Innovation for more information at research.conestogac.on.ca.