Students and faculty from Conestoga’s School of Engineering & Technology recently contributed to an international effort to help prove the quality and properties of metals printed using robotic welding technology.

A team of students and faculty from Conestoga’s School of Engineering & Technology have contributed to an international 3D metal printing project using Wire Arc Additive Manufacturing (WAAM) techniques developed through an applied research project.

The team was asked to contribute using Wire Arc Additive Manufacturing (WAAM) techniques as a result of recently published findings from an applied research project.

The international effort is part of a code case through the American Society of Mechanical Engineers to help prove to regulators of boilers, pressure vessels and pressure piping systems that components made this way perform at least as well as, if not better than, metal components manufactured with traditional methods.

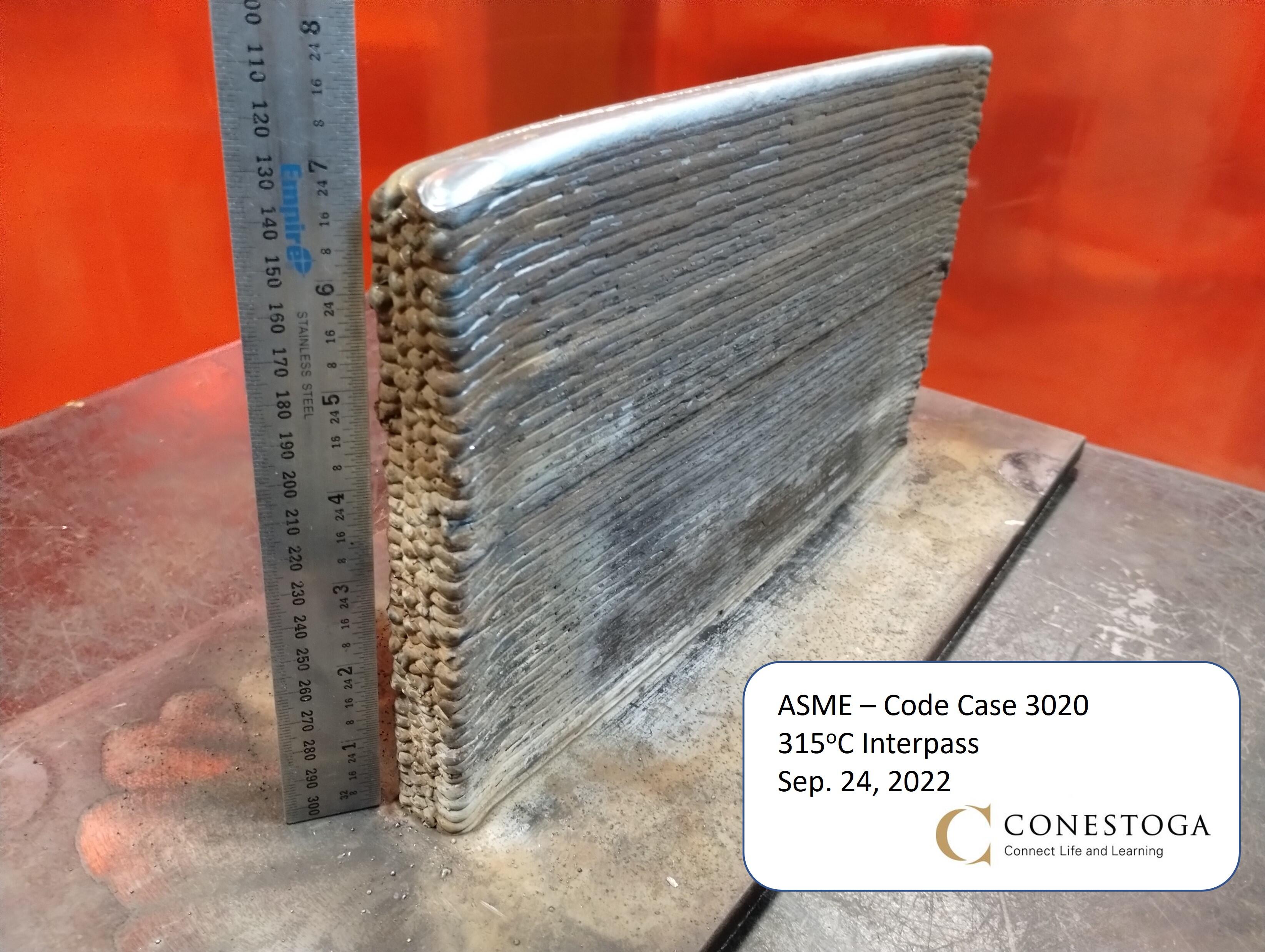

The team of students and faculty from the Manufacturing Engineering Technology - Welding & Robotics and Bachelor of Engineering - Mechanical Systems Engineering programs were supported by a recent welding & robotics graduate employed at Lincoln Electric Canada. Together, they completed two 10 kg blocks of material using the WAAM technique under carefully monitored conditions. These parts are part of a round-robin testing program where capable labs worldwide contribute printed materials.

Lincoln Electric Additive Solutions in Cleveland, Ohio, donated the welding feedstock wire for this project, and the completed parts have been shipped to the United States for detailed analysis and destructive testing.

The use of WAAM methods for large format parts has the potential to rapidly produce high-quality components with the environmental benefits of significantly less manufacturing waste than traditional subtractive techniques. In addition, it can allow Ontario manufacturers to reshore the production of parts that are currently produced overseas by forging or casting and creating high-quality jobs and new opportunities.

Conestoga’s team continues to develop this technology with ongoing research projects in the field, including developing programming methods to print objects directly from solid models.

The college works in collaboration with industry, community and government partners to deliver innovative solutions to address real-world challenges. Conestoga is ranked among Canada’s top-tier research colleges, supporting the needs of industry and community partners while providing students with opportunities to build real-world skills. Visit Conestoga Applied Research and Innovation for more information.