Third-year students in Conestoga’s Mechanical Engineering Technology - Robotics and Automation program presented capstone projects on August 16 to the college community and industry guests.

Students in Conestoga’s Mechanical Engineering Technology - Robotics and Automation program used industry software to design automated manufacturing systems for capstone projects. ACE Automation designed a system to produce, package and box custom ringed notebooks.

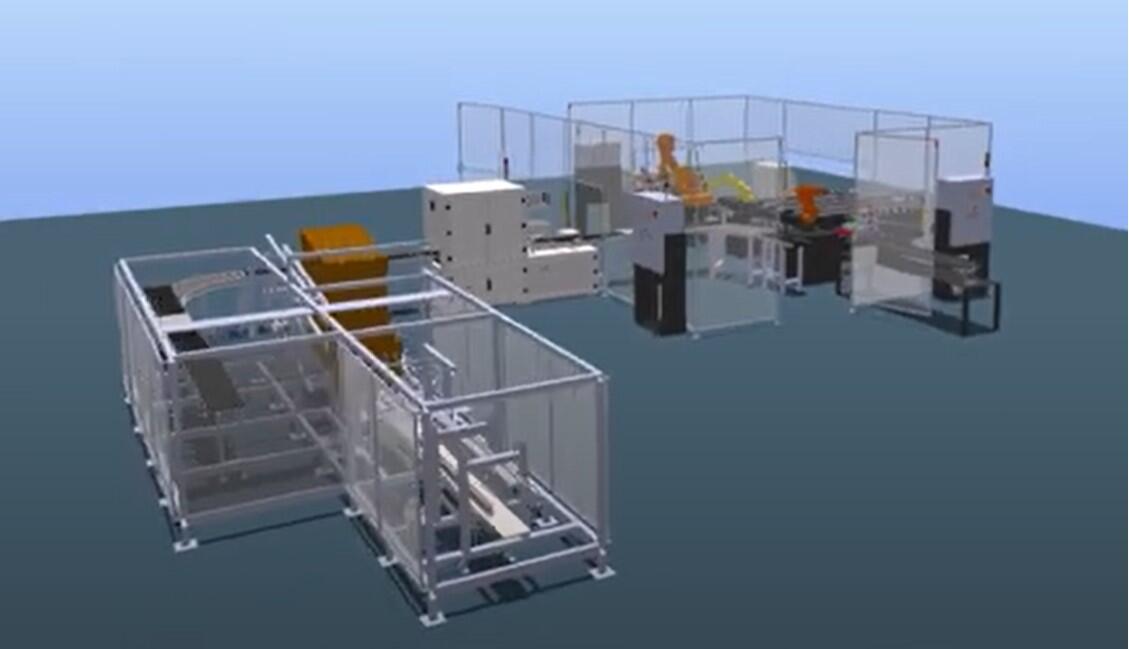

A culminating component that utilized the skills and knowledge students learned over the length of the program, each project focused on designing an automated manufacturing system that integrates advanced technologies. Working in large teams over two terms, students were required to create and present a virtual assembly line and demonstrate key deliverables, including project management, work cell design, programming, quality assurance, safety and final product design.

“The third-year robotics and automation capstone is historically a hands-on project that sees students building fully-functioning assembly lines,” said program coordinator John Tielemans. “In light of the pandemic, the project transitioned to a completely online format that had students using simulators. I’m proud to say they rose to the challenge and developed skills for online collaboration that will serve them well in the work environment of the future.”

Using software from Emulate3D by Rockwell Automation, teams built dynamic digital twins to simulate and verify the functionality of their designs. When used in industry, the software enables customers to virtually test machine and system designs before incurring manufacturing and automation costs and committing to a final build.

Students were grouped into three teams after pitching ideas and deciding as a class which ones to move forward. Team Hexa Robotics designed a process to shred, sanitize and shape plastic waste from contact lens blister packaging into toy construction blocks; ACE Automation designed a system to produce, package and box custom ringed notebooks; and Velosibotics designed an automated line to fabricate, assemble and package ultraviolet sanitizers for medical/dental and personal use.

“The design, programming and debugging of complete virtual assembly lines using Emulate3D has proven invaluable in building the skills these graduates will use in the new way of working,” Tielemans continued. “All three teams should be very proud of the extraordinary projects they have created.”

Conestoga’s Mechanical Engineering Technology - Robotics and Automation advanced diploma program combines theoretical knowledge with applied skills in the control of robotic and automated equipment using electronics, programmable automation controllers, computers, hydraulics and pneumatics. Emphasis is placed on effective techniques for designing, modifying, installing, testing, maintaining, repairing, and troubleshooting equipment and systems.