Conestoga’s School of Engineering & Technology has been working to help support health-care providers across the community as they continue to battle against COVID-19. Over the last month, 3D printers normally used by students and researchers have been put to work to build certified pieces for personal protective equipment (PPE) in high demand.

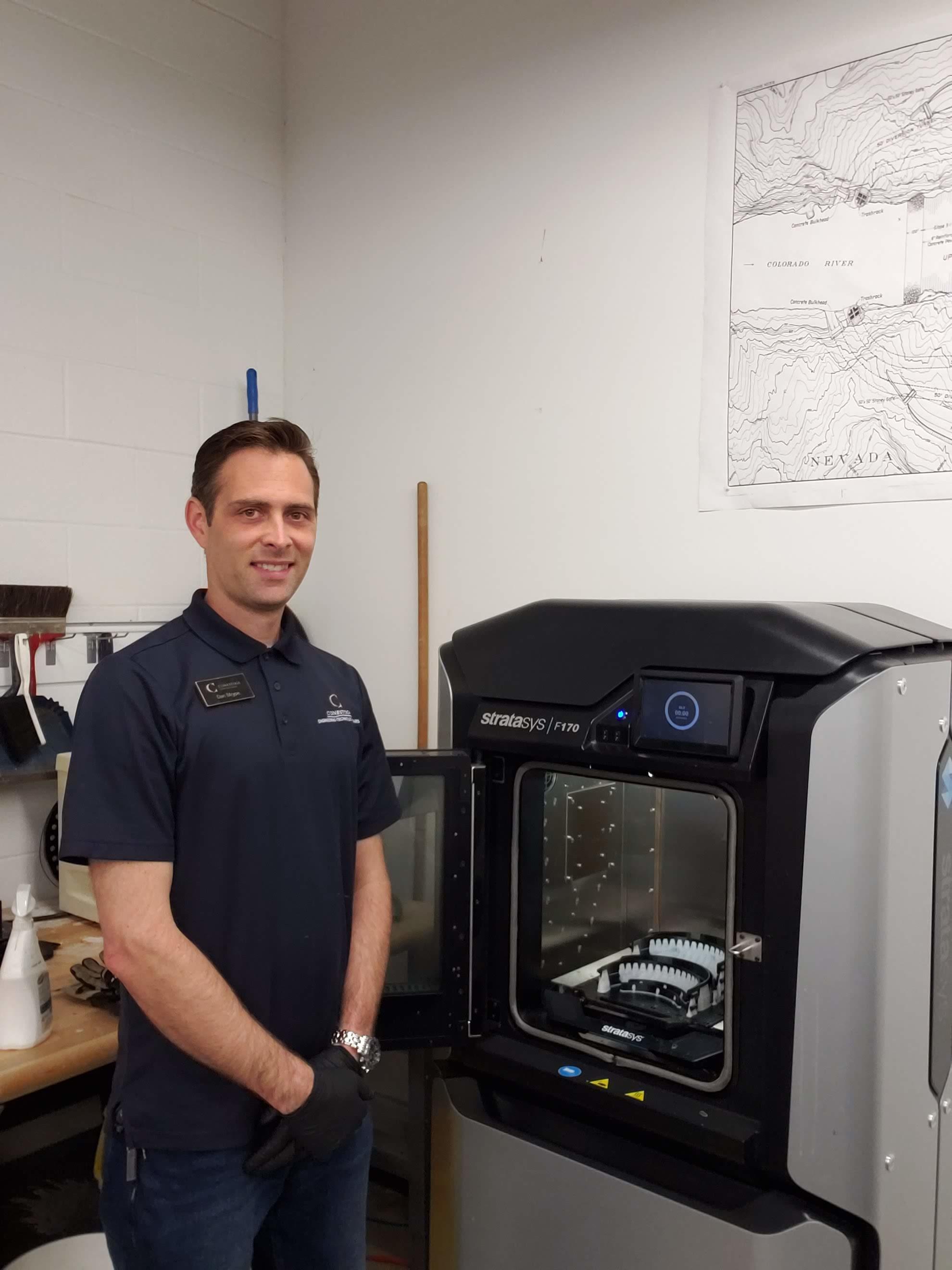

Technologist Daniel Strype (pictured) and researcher Adam Sanderson have been producing face shield headbands with 3D printers at Conestoga in support of a community PPE program.

Technologist Daniel Strype and researcher Adam Sanderson have been producing face shield headbands with equipment at the college’s Cambridge campus and the Applied Research and Innovation hub at 96 Grand Ave. The initiative is in support of The Community Shield -- a program established by Kitchener company InkSmith to address a looming PPE shortage.

“When the pandemic hit here in Waterloo region the news was full of stories about PPE shortages,” said Strype. “Our team wanted to help.”

In late March, the federal government called on post-secondary institutions to mobilize resources and expertise to help fight COVID-19. A similar call was made to Canadian manufacturers to assist in meeting the need for medical supplies and equipment.

Under the direction of Tony Thoma, executive dean to the School of Engineering & Technology, a small group was assembled to explore how resources normally used for hands-on learning could be shifted to support front-line workers. Conestoga joined a community of local makers and other institutions with 3D printers to help InkSmith produce face shields to be donated to hospitals and health-care providers.

The group worked quickly to set up machines and develop print jobs using digital plans supplied by InkSmith to ensure an efficient output. As machine operators, Strype and Sanderson have been producing roughly 100 headbands a week using ABS plastic filament. Strype manages three printers at Cambridge and Sanderson works with one at Applied Research and Innovation. Each machine is capable of printing five units per run over a 20-hour period.

Pieces supporting The Community Shield are dropped off at Kwartzlab in Kitchener where they are sanitized, assembled and distributed. Face shields are already in circulation at several local long-term care facilities and hospitals, including Cambridge Memorial, Grand River and St. Mary’s.

“If we all do what we can -- be it social distancing, checking in on those in need or supporting those on the front lines -- we will overcome this,” said Strype. “Adam and I are grateful Conestoga has allowed us to do our part by supporting this effort.”

The School of Engineering & Technology offers a comprehensive suite of programs with a wide range of credentials. Conestoga is the only college in Ontario to offer fully accredited engineering degrees. Programs feature project-based learning, co-op work experience and applied research opportunities to prepare graduates for success in their chosen fields.